- starts a day with a smile

Canister design mixes 8 adult brushes + 2 children’s brushes.

Colorful life starts with “teeth”

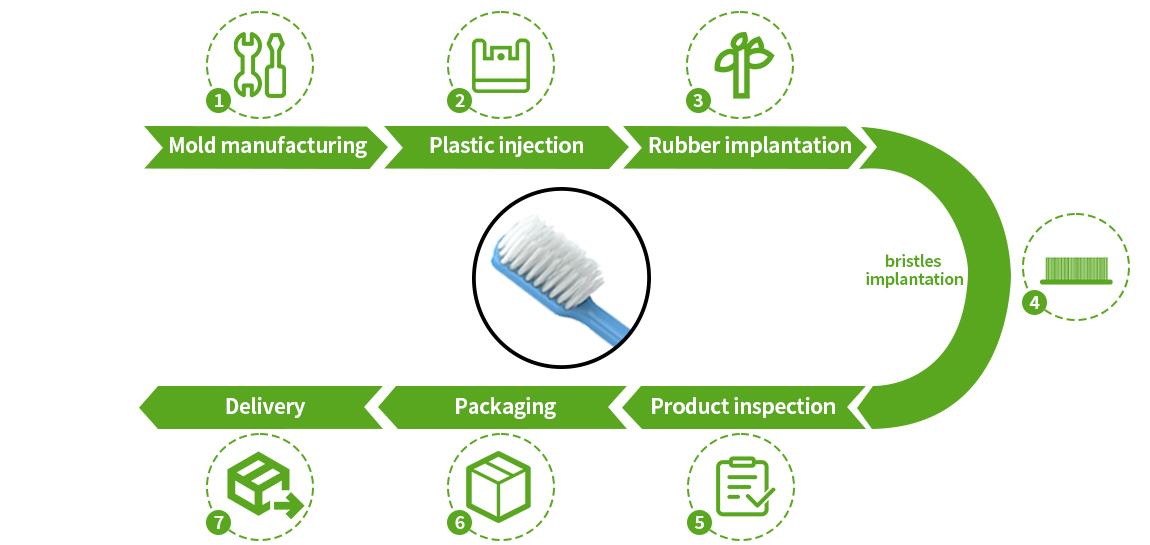

More than 30 years of experience in toothbrush mold manufacturing, complete the design, processing, scheduling, repair, maintenance of one-stop processing and manufacturing.

Single and multiple material injection molding process.

Full-automated production management.

International brand material supplied, good appearance and stable quality.

10 grinding heads are used to proceed the nylon 610,612 filament tip round grind, excellent comfortable brush feeling.

Easy handled bristle implanted in special-shaped holes with different specifications.

ISO standard production management system.

BRC, GMP820 was applied for quality assurance.

Full inspection during the process of bristle planting and packaging.

One of the largest toothbrush testing laboratories in Guangdong.

Adopts ZAHORANSKY German packaging machines and other advanced international automatic assembly line equipment.

High packaging efficiency and thermal sealing efficiency, more than 95% thermal sealing area.

High efficiency production with fast delivery time.

Located in coastal city gets convenience transportation.

Get A Quote

Established in 1993, Sugere is a well-known national brand bulk toothbrushes and toothpaste manufacturer in China, offering excellent oral care products wholesale and OEM/ODM services for global partners.